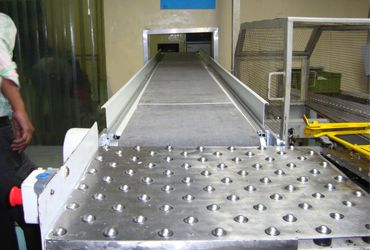

Belt Conveyor

A belt conveyor is a widely used material handling system that utilizes a continuous loop of flexible material, or belt, stretched between two or more pulleys to move items from one place to another.

Key features :

- Robust design

- Simple construction

- Light weight

- Operational consistency

- Highly energy efficient

- Low maintenance

Specification:

| Width | 100 mm to 1500mm |

|---|---|

| Length | 1 meter to 25 meters |

| Speed | 2 to 20 mtr/ min |

| Conveyor Belt material | PU/PVC/NOVA |

| Supporting Structure | Aluminum / MS / SS |

| Load capacity | 150kg/ mtr |

Applications:

Belt conveyors are highly versatile and used in a wide range of industries for various purposes, including:

- Manufacturing and Assembly: Moving components and products along production lines.

- Logistics and Warehousing:

- Sorting and transporting packages and goods.

- Mining: Transporting bulk materials like coal, ore, and gravel.

- Food Processing:

- Airports: Baggage handling systems.

- Construction: Moving materials on construction sites.

- Recycling: Transporting and sorting recyclable materials.

Advantages:

Belt conveyors offer numerous benefits, including:

- Efficiency: Streamlining material handling and increasing productivity.

- Versatility: Handling a wide range of materials.

- Safety: Reducing manual handling risks.

- Cost-effectiveness: Offering a cost-efficient solution, especially for long distances.

- Reliability: Providing a dependable and continuous flow of materials.